Dredging is a cost-effective, common solution for removing and treating contaminated sediment in a waterway. Dredging done correctly doesn’t hurt water quality, and can yield positive environmental results. However, ensuring these good results demands monitoring for contaminant release, sediment resuspension, and other water quality issues.

In this post, we’ll cover some of the basics on using a turbidity buoy at dredge sites, including the right types of buoys of the job and their features, and assembly and deployment.

Turbidity monitoring buoys for dredge projects

Before ever deploying your turbidity buoy at the dredge site, it will be essential to conduct a careful environmental assessment. To understand the full range of possibilities, background monitoring from one or more permanently moored monitoring stations is necessary. This allows project managers to get consistent data on local ecological conditions.

Typically, permanently moored monitoring stations for background monitoring will be on buoys equipped with acoustic doppler current profilers, turbidity sensors, and multi-parameter water quality sondes. These instruments need to be placed strategically within the monitoring system and inside the dredge site itself to ensure quality, reliable data and avoid misleading results.

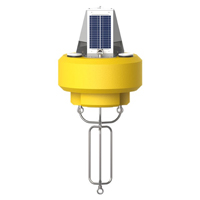

Turbidity monitoring systems for dredge projects are usually customized to fulfill project specifications, but they do share some basic qualities. To last under the rugged conditions of a dredging project, they must have a tough, durable hull and mooring system. Atop that base should be a frame for solar power that is a high-visibility stainless steel frame holding solar panels. That frame should also have the capacity for telemetry equipment, and electronics, including as many sensors as needed for the application.

These systems typically transmit data on turbidity conditions according to the parameters set by the user, but often they will send data every 10 to 30 minutes—and sometimes even more frequently. This way, dredge operators have access to continuous, real-time data no matter where they are, so long as they have access to a single computer, smartphone, tablet, or network. Careful planning of data reporting and telemetry systems is critical to making sure dredging operations go forward without problems—and that, should parameters be exceeded, any control measures can be immediately be implemented.

Turbidity monitoring buoys for dredge projects are deployed as surface buoys, so they balance the need for buoyancy with compact size and ease of deployment. They are usually constructed with a durable polymer-coated foam hull to achieve that goal.

These buoys also come equipped with a rechargeable battery pack and a solar power system for remote deployments. While not all buoys sold for this purpose are so appointed, this kind of backup power system helps prevent gaps in service and costly delays, not to mention the integrity of your data.

The sensors on the buoy include a turbidity sensor and a data logger with the right telemetry options for the setting. An antifouling wiper for the sensor is usually advisable. In most cases, it’s possible to customize this kind of data buoy with other types of sensors such as DO sensors, fluorometers and CTDs.

Deploying the turbidity buoys for dredge sites

To ensure accurate, reliable data, it is critical to calibrate all sensors for your turbidity buoy system onshore, shortly before deployment. Attach all ballast weights, sensors, solar panels and towers, if needed, before ever leaving the shore.

Moreover, you should test each piece of equipment, from the data logger, sensors and software to telemetry, separately and together, before they ever touch the water. This allows you to verify that everything is functioning optimally, but it also confirms that your team knows how to handle the system before deployment.

The right turbidity buoys for dredge projects

Although there are many turbidity monitoring sensors, instruments, and systems on the market, some are better than others for monitoring dredge sites. Here are some of our top picks for monitoring dredge sites.

Accuracy is the watchword when it comes to sondes, and that’s why we like the YSI EXO2. The next-generation sonde platform offers a chemistry-free anti-fouling system, a highly efficient power management platform, and durable construction, allowing it to function trouble-free for up to 90 days between maintenance visits. The EXO2 sonde includes six sensor ports and a central anti-fouling wiper option. Possible sensor parameters include conductivity, depth, dissolved oxygen, fluorescent dissolved organic matter (fDOM), ORP, pH, salinity, specific conductance, temperature, total algae (phycocyanin and chlorophyll), total dissolved solids (TDS), and total suspended solids (TSS) in addition to turbidity.

The rugged NexSens CB-450 offers your dredge project the long-term durability you’re after. With 450 pounds of buoyancy, 30W of solar power, and a range of mounts for multiple instruments and sensors, this buoy is up to just about any project.

The CB-450 turbidity buoy is constructed of cross-linked polyethylene foam wrapped in a skin of tough polyurea. Atop the buoy is a 20-inch, stainless steel tower. The tower holds an instrument well and three 10-watt 12VDC unbreakable solar panels. The center instrument well is 10 inches in diameter and 18 inches tall and is designed to accommodate data loggers, batteries, sensors and more. It’s also easy to use, with three 4-inch pass-through holes for quick connections and deployment pipes.

Wireless telemetry options for the CB-450 turbidity buoy include cellular, Iridium satellite, spread spectrum radio, and Wi-Fi. This system is compatible with both analog and digital sensor interfaces, including RS-485, RS-232, VDC, SDI-12, mA, and pulse count varieties.

Without access to them, real-time data are not that useful. That’s why the 24/7 access to remote data from any computer, trend tracking, instant alarm notifications, and the data-powered, intuitive ease-of-use WQData Live helps you get more out of this system’s real-time data. These tools allow dredge operators to access turbidity data in real-time and deploy field staff to monitor water conditions as needed. This way managers can demonstrate their projects are meeting technical requirements, generate reports to prove it, and ensure their operations do not cause particle re-suspension problems by quickly resolving issues.

The bottom line

Dredge projects demand careful attention and monitoring according to set standards. Quality and real-time access are critical to getting the job done properly. To learn more about designing a turbidity monitoring system, or using one at a dredge site, reach out to the NexSens team. We are here for all of your dredge site monitoring questions.

Equipment

The NexSens CB-450 Data Buoy is designed for deployment in lakes, rivers, coastal waters, harbors, estuaries and other freshwater or marine environments.

The EXO turbidity sensor is a digital smart sensor featuring welded titanium construction and wet-mateable connectors.

WQData LIVE is a web-based project management service that allows users 24/7 instant access to data collected from remote telemetry systems.

0 comments