Thermal Effluent Monitoring

Power plants, paper and steel mills, refineries, and other large industrial facilities often use water for cooling. When heated process waters are then discharged back into surface waters, this can potentially cause thermal pollution and negatively impact ecosystems. Thermal effluent monitoring systems help ensure that process waters are sufficiently cooled before discharge, thereby protecting aquatic flora and fauna.

Thermal Effluents

Thermal Effluent Monitoring System

In the United States, the 1972 Clean Water Act put into place limits on thermal effluents to assure protection of water bodies. Although somewhat varied in application, National Pollution Discharge Elimination System (NPDES) permits are the typical means used to enforce this law. Automated thermal effluent monitoring systems may be used to ensure and document compliance with NPDES or other local regulatory requirements.

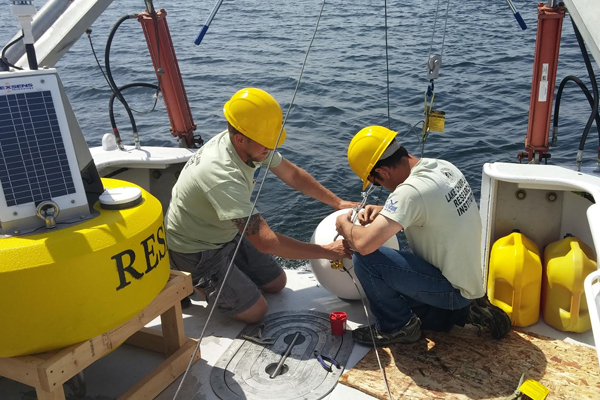

A typical system consists of multiple temperature measurement stations located at intake sites, cooling ponds, discharge channels, outlet points and/or downstream of the plant facility. At some locations, a mast-mount configuration based on the X3 environmental data logger and SP-Series solar power pack is the simplest setup. Sites requiring measurement on open water can benefit from a buoy platform such as the CB-250 data buoy with buoy-mounted X3 data logger.

In both cases, single-point temperature measurements can be recorded using the fast-response T-Node FR temperature sensor. If measurements are required at multiple depths, sensors can be delivered in profiling strings, either with a modular configuration based on the T-Node FR or fixed TS210 thermistor strings.

Flexible communications from the X3 data logging platform transmit data wirelessly to the WQData LIVE web datacenter, which includes a rich feature set for viewing, manipulating, reporting and exporting of data.

The multiple sensor ports and large sensor library of the X3 data logger also facilitate multi-sensor deployments with a wide range of instrument types. For example, multi-parameter water quality sondes can measure temperature together with DO and other water quality parameters at locations where effluent is discharged back into surface waters. Other instruments like water level sensors, velocity/flow meters and weather stations can simultaneously record other parameters which may be of interest to plant operations.

Contact a NexSens Applications Engineer today to discuss your thermal effluent monitoring application.

Case Studies

Managing Plant Discharge Temperatures

The Southern Illinois Power Cooperative operates a power plant near Lake of Egypt around the clock to produce energy for its customers. Key to continuing its operations is minimizing stress on plant infrastructure by pumping in water from the lake to cool the generators. The heated water must then be condensed and cooled before it can be discharged back into the reservoir. NexSens monitoring buoys ensure that the reservoir water temperature isn't impacted by discharge waters.

Read MoreMonitoring An Active Thermocline, Rapid Changes

Beginning in the 1990s, researchers have collected samples manually every few weeks on trips to Lake Champlain to gather data on its dynamics. To help provide a more complete picture, researchers from the State University of New York (SUNY)—Plattsburgh deployed a cellular data buoy in the lake near Valcour Island. The buoy incorporates a weather station, water quality sensors and NexSens TS210 thermistor string to measure the thermocline.

Read MoreWashington Reservoir Temperature Changes

The many major rivers of the Pacific Northwest such as the Columbia, Snake and North Fork Clearwater are outfitted with various dams and reservoirs. These serve many purposes including flow control, energy production, plant cooling, and drinking water supply. The U.S. Army Corps of Engineers (USACE) Walla Walla District plays a big hand in managing and maintaining river infrastructure and uses NexSens thermistor strings to closely monitor temperatures.

Read More