The NOAA Chesapeake Bay Office runs an unusual set of buoys. NOAA’s Chesapeake buoys originated as part of the John Smith Water Trail—a kind of aquatic Appalachian Trail for boaters.

The NOAA Chesapeake Bay Office runs an unusual set of buoys. NOAA’s Chesapeake buoys originated as part of the John Smith Water Trail—a kind of aquatic Appalachian Trail for boaters.

Although the buoys are no longer used as interpretive trail markers, they are now part of a larger observing system of 10 full-time stations.

Challenge: Weighed down

In the past, the team used the AXYS WatchKeeper buoy at these stations—but these buoys weigh in at around 4,500 pounds each, including anchor. This meant that the NOAA team had to contract out all deployments and retrievals.

“You don’t have to lift it all at once, but the amounts you do have to lift are heavy, and most of the ships that can do that have a deep draft,” remarks Byron F. Kilbourne, an oceanographer at the NOAA Chesapeake Bay Office. “The areas that we’re working in are pretty shallow. The bigger boats that can handle that equipment would chew up our annual vessel contract budget in one trip.”

The NOAA team’s goal in the past was to find vessels that could handle the AXYS buoys within budget. This has, in turn, led them to struggle to respond to various problems in a timely way.

Lightening the load

For over two years, the NOAA Chesapeake Bay Office has been partnering with NexSens on this challenge and its pain points:

- too much weight

- a need to use a contractor

- a need to find a contractor within budget

- delays in responding to problems, or inability to stay within budget

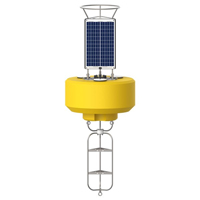

The NexSens CB-1250 data buoy systems were the best solution to this problem. The NexSens buoy brings NOAA the flexibility to bring many of their vessel operations in-house and broadens the spectrum of contractor vessels that are appropriate for each job.

More speed, less effort

The biggest difference in the two buoys for the NOAA team during the deployment process is weight, not total size.

“We’re able to totally instrument the NexSens CB-1250 buoy, and have it completely plugged in and sampling, as if it was in the water, on-deck,” states Dr. Kilbourne. “This way we can pick it up from the side, and drop the whole buoy in, tested, working, and ready. The whole deployment, from the time we get on-station to the time we’re driving away, is less than an hour.”

Retrieval is also easy. The team can pull the superstructure off in one lift, and then the buoy up in one lift, greatly simplifying operations.

Easier operations and lower costs mean better data

Easier deployment and retrieval also means better, more reliable data. The NOAA team confirmed this just a day or two after getting the Jamestown buoy in the water.

“We’re not sure how, but the buoy got pulled up into the shallow mud in the riverbank, and we had to pull it off,” Dr. Kilbourne says. “We did that with our own vessel, not with a contractor, so because of the buoy, we were able to respond in a timely way. That’s a huge help to our maintenance effort.”

Keeping your instruments online is essential to your research and monitoring efforts. NexSens equipment is designed and built to do just that, and we can help you get started. Find out more from a member of our team today.

Equipment

The CB-1250 offers increased flotation and solar charging for heavy or power-hungry sensors while still maintaining a relatively small footprint.

The SVS-603 Wave Sensor is a highly accurate MEMS-based sensor that reports heading, wave height, wave period and wave direction via RS-232 or logs to its on-board data logger.

The YOUNG Serial Output Wind Monitor combines the performance and durability of the standard Wind Monitor with a unique optical encoder direction transducer and serial output.