Custom Data Buoy Configuration Guide

While many NexSens data buoys are delivered as turnkey systems featuring a NexSens X-Series data logger, they are also designed to support custom integration of user-supplied, third-party electronics. The CB-Series data buoys from the CB-150 and larger are designed with an open data well in the center of the hull to facilitate such deployments.

Figure 1: From left to right, CB-150, CB-250, CB-450, CB-650, CB-950 and CB-1250 data buoys.

The aim of this guide is to describe the options and design process for configuring a custom system using the CB-Series data buoy platforms. The topics considered are (click to jump to a section):

Selecting a Buoy Platform

The first step in designing a custom buoy system is to choose a buoy platform. The CB-Series data buoys range in size from the small and portable CB-150 with 150 lb (68 kg) net buoyancy and 24” (61 cm) hull diameter to the large and powerful CB-1250 with 1250 lb (567 kg) gross buoyancy and 48” (122 cm) hull diameter. An overview of the complete line of buoys is available in the CB-Series comparison chart.

Buoyancy, power supply, physical space in the watertight data well for mounting user-supplied electronics, and mounting options for specific sensor types are the main criteria used to determine which platform is best suited for a particular application. These factors are discussed in more detail in the following sections.

Figure 2: Buoy hull X-ray view showing data well with battery harness, data well lid, and instrument pass-through holes.

Buoyancy Requirements

Determining minimum required buoyancy is a fairly straightforward process. Calculate the total in-water weight of the sensor payload and mooring hardware to be used. Compare this to the net or gross buoyancy of the platform(s) under consideration, keeping in mind that the value listed in the datasheet is the absolute maximum the buoy can safely handle. Allowing a minimum 25% margin is recommended. Remember to account for potential changes during the deployment of the buoy system, such as weight added due to biological growth on the buoy hull, frame and mooring system.

In many cases, a weight to net or gross buoyancy calculation is not the only buoyancy-related consideration. Any deployment location subject to substantial waves, currents and/or periodic rough conditions may be hazardous for smaller platforms. Although watertight, buoys should not be submerged for best performance. A factor of 100% surplus buoyancy or more may be desirable.

For more information on buoy buoyancy and stability, see CB-Series Data Buoy Ballast Weight & Stability.

Power Requirements

Power supply is the second primary factor that drives buoy selection, and very often the controlling factor. The size of solar panels varies by buoy model, as does the height of the data well where battery packs are mounted. Proper sizing of a power system requires calculation of the combined demand of the data logger, sensors and other electrical components of the system and determination of the estimated solar insolation at the geographic location where the buoy will be deployed.

To aid with system power analysis, NexSens has developed a power budget calculator that factors in the system variables and allows for custom inputs. This tool is available from NexSens upon request.

Battery packs are available from NexSens or can be user-supplied. NexSens CB-A05-X battery harnesses include a solar regulator, sealed lead acid (SLA) batteries, and mounting bracket for secure installation in the buoy data well. The compatible battery harnesses by buoy model are as follows:

CB-A05-1

| CB-A05-2

| CB-A05-3

| CB-A05-4

| |

| CB-150 | x | |||

| CB-250 | x | x | ||

| CB-450 | x | x | ||

| CB-650 | x | x | x | |

| CB-950 | x | x | x | |

| CB-1250 | x | x | x | x |

For additional relevant specifications and capacity information for the battery harnesses, see CB-Series Buoy Battery Capacities.

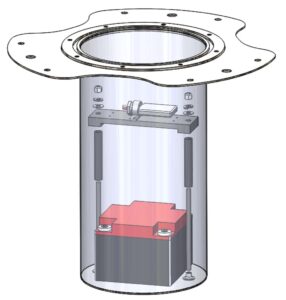

For user-supplied battery packs, there are two threaded hubs in the bottom of the data well spaced 7-¾” (19.7 cm) apart (note minor variation may be possible due to welding process). These allow connection of 3/8″-16 threaded rod which can be locally sourced or supplied by NexSens (part number N11149). A predesigned bracket like what is used in the CB-Series battery harnesses can optionally be supplied as well (part number CB0468).

Figure 3: Data well internal view with optional battery mount hardware pictured.

Aside from the threaded hubs, there are no built-in connection points inside of the data well. However, wedge-shaped and round foam inserts sized for the data well can also be provided to help secure mounted electronics and prevent items from moving inside the data well. Part numbers are:

- CB0161 – wedge-shaped for packing batteries and other sqaure-shaped items

- CB0162 – round with small center hole cutout

- CB0163 – round with large center hole cutout

Warning! The data well is constructed entirely of 316 stainless steel. Use extreme caution when installing or replacing any batteries in the data well. Any contact between the walls of the data well and battery poles can cause short-circuiting. This includes through metallic tools used to tighten connections. Always use tools with rubber grips when handling batteries.

Data Well Size Requirements

Adequate physical space in the data well is necessary for placing any electronics that must be kept free from moisture. All CB-Series data buoys have the same data well inner diameter of 10.3” (26.2 cm). The height of the data well varies based on buoy model:

| Model | Data Well Height (in) | Data Well Height (cm) |

| CB-150 | 13.5″ | 34.2 cm |

| CB-250 | 19.5″ | 49.5 cm |

| CB-450 | 19.5″ | 49.5 cm |

| CB-650 | 21.5″ | 54.6 cm |

| CB-950 | 25.5″ | 64.8 cm |

| CB-1250 | 27.5″ | 69.9 cm |

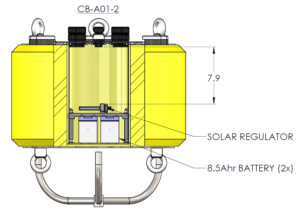

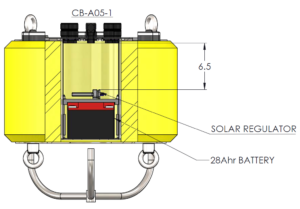

The drawing sets in the Knowledge Base show how much space remains in the data well of each buoy model with a battery harness installed. The below examples show a cutaway view of the data well of the CB-150 with CB-A01-2 and CB-A05-1 battery harnesses, respectively. The given dimension is in inches.

Figure 4: CB-150 with CB-A01-2 Battery Harness. |  Figure 5: CB-150 with CB-A05-1 Battery Harness. |

As mentioned above in the Power Requirements section, the data well is a hollow cylinder constructed of stainless steel that has no built-in connection points aside from the two threaded hubs on the bottom surface.

Sensor Mount Requirements

Both standard and sensor-specific mounting hardware is available for the CB-Series data buoys.

A common feature of all buoy hulls is a set of three pass-through holes for routing instrument cables from the data well to below the water surface while keeping them well protected. The pass-through holes vary from 2” on the CB-150 and CB-250 to 8” on the CB-1250.

| Model | Pass-Through Hole Diameter (in) | Pass-Through Hole Diameter (cm) |

| CB-150 | 2.0″ | 5.1 cm |

| CB-250 | 2.0″ | 5.1 cm |

| CB-450 | 4.0″ | 10.2 cm |

| CB-650 | 4.0″ | 10.2 cm |

| CB-950 | 6.0″ | 15.2 cm |

| CB-1250 | 8.0″ | 20.3 cm |

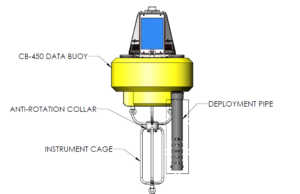

Optional 91xM deployment pipes can thread directly into the bottom of the pass-through ports to provide for secure placement of sensors with topside access for maintenance without having to remove the buoy from the water. This is sometimes a preferred solution compared to fixing sensors onto the instrument cage below the buoy. In such cases, the pass-through port size may be a determining factor for buoy selection. For example, although the CB-250 and CB-450 models provide the exact same power capacity, the CB-450 with its 4” pass-through ports would be a better option to deploy a water quality sonde with 4” diameter.

Figure 6: CB-450 view showing 4″ pass-through holes. |  Figure 7: CB-450 with 914M instrument deployment pipe. |

Some mounting hardware is designed for a specific buoy model. For example, the Nortek Aquadopp ADCP Buoy Mount fits only into the 6” pass-through port of the CB-950 or the 12” pass-through port of the CB-1250.

A list of top-side and subsurface sensor mounting accessories is available here.

In the design process, consider what instruments will be mounted onto the buoy and how well-suited the selected buoy is for accommodating them.

Selecting a Data Well Lid

Once the buoy platform is selected, the data well lid is the next component to determine.

There are four alternatives for data well lid. The selection criteria are given below, and the standard and optional parts are listed for each lid type. Those marked with a ¹ are included standard with the respective lid, and those marked with ² are options that must be ordered separately.

- The CB-PTL Pass Through Lid is the simplest and most common lid type for deployments in freshwater and some marine environments where full buoy submersion is not a high risk. It features gland fittings for passing through cables with bare leads, which are tightened around the cable jacket to create a seal. For pluggable connections, sensor and RF bulkhead adapters are available. Contents and options:

- UW6-BULK Power Bulkhead Cable Assembly¹

- Standard pressure release valve¹

- (6) sensor port openings

- Set of (6) sensor port plugs¹ (for unused ports)

- Set of (6) gland fittings¹

- Spare O-rings and grease¹

- RF-BULK RF Bulkhead Connector Assembly²

- UW-BULK Sensor Bulkhead Connector Assembly² (requires UW-CON connectorization of sensor cable)

- SA1352 CB-Series battery harness cable adapter² (connects UW6-BULK to a CB-A01-2/CB-A05-X battery harness)

- The CB-MCL wet-mate Marine Connector Lid incorporates all marine-grade wet-mate connectors and a 5 psi UW-PRV Pressure Relief Valve. It is ideal for harsher marine environments where occasional full buoy submersion is a concern. Contents and options:

- CB-MCL Solar Connector with UW6 Solar/COM port adapter¹

- UW-PRV Pressure Release Valve¹

- Bushing connector¹

- Can optionally be replaced with RF-BULK RF Bulkhead Connector Assembly²

- (5) sensor port openings

- (5) MCBH Connector Port Plugs¹ (for unused ports)

- MCBH Male Bulkhead Connectors² (4-pin, 5-pin, 6-pin or 8-pin, use with MCDC Female Dummy Plugs²)

- MCBH Female Bulkhead Connectors² (4-pin, 5-pin, 6-pin or 8-pin, use with MCDC Male Dummy Plugs²)

- No lid provided. User can machine own plate using dimensional drawing with bolt hole locations provided by NexSens.

Selecting Accessories

Besides sensor mounts previously mentioned, there are many accessories that can be added to CB-Series buoy systems. In many cases these are optional, but in some cases they are strongly recommended, such as the addition of sacrificial zinc anodes for use in saltwater. The table below lists the most common accessories with description of the use cases.

| Part (link) | Description | Use Cases | |

| M550-F-Y | Solar marine light with flange mount & 1-3 nautical mile range, 15 flashes per minute, yellow | For nighttime visibility on CB-150, CB-250 and CB-450 buoys |

| M650H-Y | Solar marine light with 4 nautical mile range, 15 flashes per minute, yellow | For nighttime visibility on CB-650, CB-950 and CB-1250 buoys |

| CB-RR | Radar reflector for CB-Series data buoys | For visibility on ship radar screens, mounts to CB-650, CB-950 and CB-1250 buoys |

| CB-CCA | Cage anti-rotation collar for CB-Series data buoys | For strengthening connection of instrument cage on CB-150, CB-250 and CB-450 buoys (included with CB-650 and larger) |

| CB-ZA | Sacrificial zinc anode for CB-Series data buoys | For protection of stainless steel frame when used in saltwater, recommended two per buoy, requires periodic replacement |

| CB-PW-AC-30W | Battery float charger for CB-A01-2 battery harness, UW 6-pin plug to AC adapter, 30W | For charging CB-A01-2 battery pack without opening the buoy data well |

| CB-PW-AC-60W | Battery float charger for CB-A05-X battery harness, UW 6-pin plug to AC adapter, 60W | For charging CB-A05-X battery pack without opening the buoy data well |

| BALxx | Ballast weight for CB-Series data buoys, 25 – 150 lb. (11.3 – 68 kg) | For adding counter-ballast to buoys, see recommended ballast weights by buoy model |

| 91xM | Deployment pipe assembly with stop bolt & threaded male adapter, schedule 80 PVC, 32″ length | For secure, near-surface instrument deployment with topside access for maintenance |

Creating a Parts List

By following the design process described above, a parts list for the custom buoy system can be developed. To further simplify the process and to receive pricing for a custom system, fill out and submit the Custom Buoy Configurator form.